How to Splice Low Voltage Landscape Lighting Wire: A Comprehensive Guide

Low voltage landscape lighting enhances the beauty and security of your outdoor spaces. However, installing or repairing these systems often involves splicing wires. Knowing how to splice low voltage landscape lighting wire correctly is crucial for ensuring a safe and reliable connection. This comprehensive guide provides step-by-step instructions, safety precautions, and essential tips for successful low voltage landscape lighting wire splicing.

Understanding Low Voltage Landscape Lighting

Before diving into the splicing process, it’s important to understand the basics of low voltage landscape lighting. These systems typically operate at 12 volts, reducing the risk of electric shock compared to standard household voltage (120V). Common components include a transformer, low voltage wiring, and light fixtures. The transformer converts household voltage to the lower voltage required by the landscape lights.

Why Splicing is Necessary

Splicing becomes necessary when extending wiring, repairing damaged sections, or connecting multiple light fixtures to the main cable. A well-executed splice ensures consistent power delivery to all lights and prevents potential hazards like short circuits or voltage drops. Improperly spliced wires can lead to system failures, flickering lights, or even electrical fires. Learning how to splice low voltage landscape lighting wire correctly is therefore a critical skill.

Tools and Materials Required

To successfully splice low voltage landscape lighting wire, gather the following tools and materials:

- Wire Strippers: Essential for removing insulation without damaging the wire.

- Wire Connectors: Waterproof connectors designed for low voltage landscape lighting are recommended.

- Electrical Tape: High-quality electrical tape for added insulation and protection.

- Utility Knife: For cutting and trimming wires.

- Gloves: To protect your hands.

- Safety Glasses: To protect your eyes.

- Voltage Tester: To ensure the power is off before working on the wires.

- Low Voltage Landscape Lighting Wire: Use the correct gauge wire for your system.

Step-by-Step Guide: How to Splice Low Voltage Landscape Lighting Wire

Follow these steps to safely and effectively splice low voltage landscape lighting wire:

Step 1: Safety First – Disconnect the Power

Before starting any electrical work, always disconnect the power supply. Locate the transformer and unplug it or switch it off. Use a voltage tester to confirm that the wires are not carrying any current. This is a crucial safety precaution that should never be skipped.

Step 2: Prepare the Wires

Use wire strippers to carefully remove about ½ inch of insulation from the ends of the wires you want to splice. Be careful not to nick or cut the copper wire itself, as this can weaken the connection. If the wire is damaged, cut it back to a healthy section.

Step 3: Choose the Right Connector

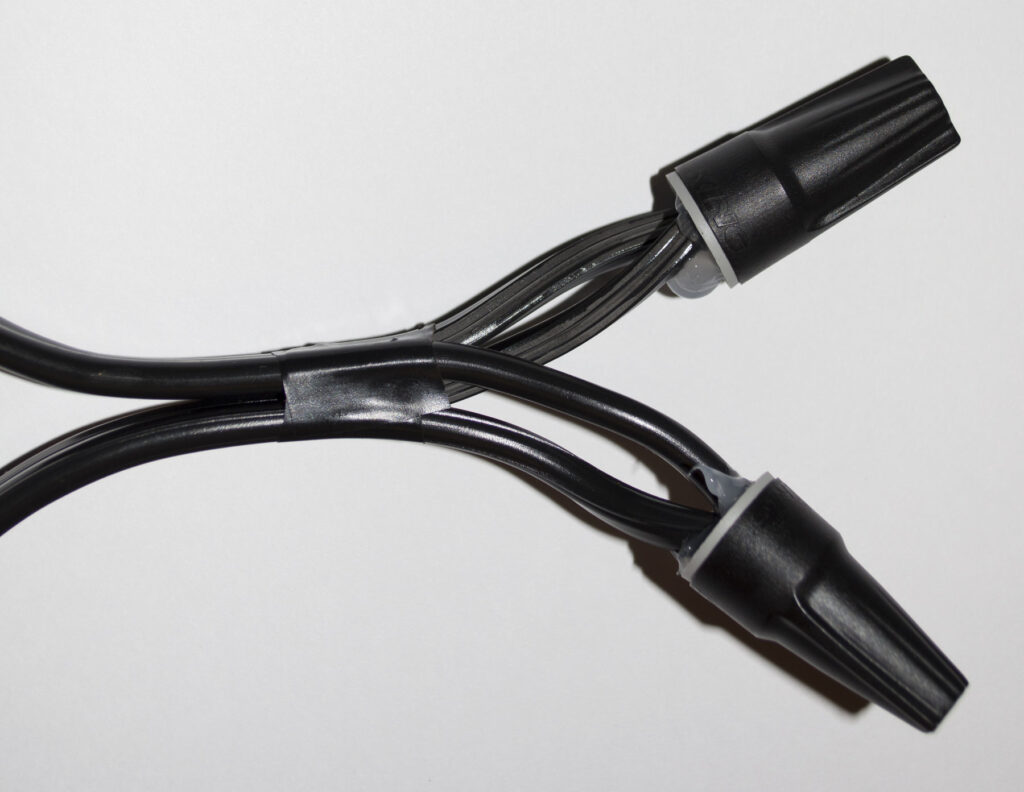

Select a waterproof wire connector specifically designed for low voltage landscape lighting. These connectors are designed to protect the connection from moisture and corrosion. There are several types of connectors available, including twist-on connectors, crimp connectors, and gel-filled connectors. Gel-filled connectors are often preferred for their superior moisture resistance. Understanding how to splice low voltage landscape lighting wire also involves choosing the right materials.

Step 4: Connect the Wires

Insert the stripped ends of the wires into the connector according to the manufacturer’s instructions. For twist-on connectors, twist the connector until the wires are securely joined. For crimp connectors, use a crimping tool to firmly secure the connection. Ensure the wires are making solid contact within the connector. This is a critical step in how to splice low voltage landscape lighting wire properly.

Step 5: Secure and Insulate the Connection

After connecting the wires, ensure the connector is tightly closed or crimped. Wrap the connector with electrical tape for added insulation and protection against moisture. This step is particularly important in outdoor environments where the connection will be exposed to the elements.

Step 6: Test the Connection

Once the splice is complete, reconnect the power supply and test the connection. Check the lights to ensure they are working properly. If any lights are not working, double-check the splice and ensure that all connections are secure.

Types of Wire Connectors for Low Voltage Landscape Lighting

Choosing the right wire connector is essential for a reliable and long-lasting splice. Here are some common types:

- Twist-On Connectors (Wire Nuts): These are simple to use and suitable for dry environments. However, they may not provide sufficient moisture protection for outdoor use unless combined with electrical tape.

- Crimp Connectors: These require a crimping tool but offer a more secure and reliable connection than twist-on connectors. Look for waterproof crimp connectors for landscape lighting.

- Gel-Filled Connectors: These connectors are filled with a gel that seals the connection and prevents moisture from entering. They are an excellent choice for outdoor use and are highly recommended for low voltage landscape lighting.

- Direct Burial Connectors: Designed to be buried directly in the ground without additional protection. They are typically gel-filled and provide a very secure and waterproof connection.

Common Mistakes to Avoid When Splicing Low Voltage Landscape Lighting Wire

To ensure a successful splice, avoid these common mistakes:

- Using the Wrong Type of Connector: Always use connectors specifically designed for low voltage landscape lighting. Standard wire connectors may not provide adequate moisture protection.

- Not Disconnecting the Power: Never work on electrical wires without disconnecting the power supply. This is a critical safety precaution.

- Damaging the Wire: Be careful not to nick or cut the copper wire when stripping the insulation. Damaged wires can weaken the connection and lead to system failures.

- Loose Connections: Ensure that all connections are tight and secure. Loose connections can cause flickering lights and other problems.

- Skipping Insulation: Always insulate the connection with electrical tape or a waterproof connector. This protects the connection from moisture and corrosion.

Troubleshooting Low Voltage Landscape Lighting Issues

If you encounter problems with your low voltage landscape lighting, consider these troubleshooting tips:

- Flickering Lights: This can be caused by loose connections, corroded wires, or a faulty transformer. Check all connections and replace any damaged wires.

- Lights Not Working: This could be due to a blown bulb, a tripped circuit breaker, or a faulty transformer. Check the bulb, reset the circuit breaker, and test the transformer.

- Voltage Drop: This occurs when the voltage at the end of the wiring run is significantly lower than the voltage at the transformer. This can be caused by long wiring runs, undersized wiring, or too many lights on a single circuit. Use thicker gauge wire or reduce the number of lights on the circuit.

- Corroded Wires: Corrosion can cause poor connections and system failures. Clean corroded wires with a wire brush and apply a corrosion inhibitor. Replace severely corroded wires.

Safety Tips for Working with Low Voltage Landscape Lighting

Follow these safety tips to protect yourself while working with low voltage landscape lighting:

- Always Disconnect the Power: Never work on electrical wires without disconnecting the power supply.

- Wear Safety Glasses and Gloves: Protect your eyes and hands from potential hazards.

- Use the Right Tools: Use tools specifically designed for electrical work.

- Work in Dry Conditions: Avoid working in wet or damp conditions.

- Inspect Wires Regularly: Check for damaged or corroded wires and replace them as needed.

Maintaining Your Low Voltage Landscape Lighting System

Regular maintenance can help extend the life of your low voltage landscape lighting system. Here are some tips:

- Clean the Lights: Clean the lenses and reflectors of your lights regularly to maintain their brightness.

- Trim Vegetation: Trim any vegetation that is blocking the lights.

- Check the Wiring: Inspect the wiring for damage or corrosion and repair or replace as needed.

- Replace Bulbs: Replace burnt-out bulbs promptly.

- Adjust the Timer: Adjust the timer as needed to reflect changes in daylight hours.

Conclusion

Knowing how to splice low voltage landscape lighting wire is a valuable skill for any homeowner. By following the steps outlined in this guide and taking the necessary safety precautions, you can ensure a safe, reliable, and beautiful outdoor lighting system. Remember to always disconnect the power before working on any electrical wires and use the right tools and materials for the job. A properly spliced and maintained low voltage landscape lighting system will enhance the beauty and security of your home for years to come. The key to how to splice low voltage landscape lighting wire is patience and attention to detail. With practice, you’ll become proficient in maintaining your outdoor lighting.

By understanding how to splice low voltage landscape lighting wire, you can save money on professional installation and repair costs. This guide provides the information you need to tackle these projects confidently. Remember to always prioritize safety and double-check your work to ensure a long-lasting and reliable lighting system. Good luck with your next project!

[See also: Choosing the Right Landscape Lighting Wire]

[See also: Troubleshooting Common Landscape Lighting Problems]

[See also: Installing a Low Voltage Landscape Lighting System]